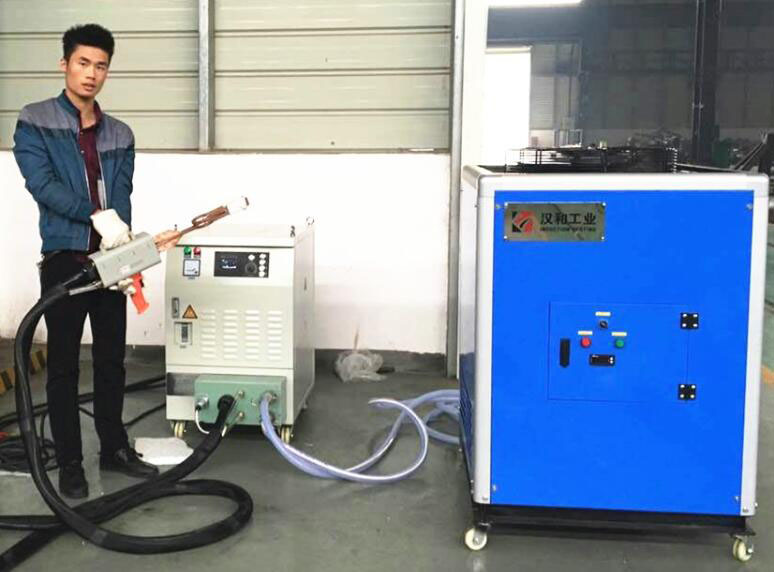

Mochini oa ho Welding oa Portable Intelligent Induction O bolokang Matla

Sebopeho

Mochini o nkehang oa induction induction o entsoe ka phepelo ea motlakase e phahameng ea transistor, thapo e tsoang hole e bonolo, coil e futhumatsang ea induction, hanger ea cable e tsoang, tora e phodileng e koetsoeng joalo-joalo.

Likaroloana

Matla a futhumatsang a sehlahisoa sena a sebelisa sesebelisoa sa puisano sa maqhubu a maqhubu a lebelo a phahameng a IGBT a phahameng ka ho fetesisa, se fetolelang matla a motlakase a maqhubu a motlakase a mekhahlelo e meraro ho ea molemong o le mong oa matla a motlakase a phahameng.Sesebelisoa sena se sebelisa molao-motheo oa induction ea electromagnetic ho beha karolo ea mosebetsi sebakeng se fapaneng sa matla a khoheli tlas'a tikoloho ea moea, vacuum le khase e sireletsang, e hlahisang tahlehelo ea hona joale ea eddy mme e hlahisa mocheso, o fihlelang litlhoko tsa smelting diathermy le quenching.Mekhoa ena ea ho futhumatsa e na le melemo ea lebelo le phahameng la ho futhumatsa, tahlehelo e fokolang ea ho chesa, matla a tlaase a mosebetsi le boleng bo botle ba sehlahisoa.Ha ho bapisoa le motlakase oa khale oa elektronike o nang le matla a mangata a matla, a ka boloka matla ka 35% le 20% ha a bapisoa le motlakase oa mehleng ea khale oa thyristor medium frequency power, 'me ha a na lerata la maqhubu a mahareng a SCR.Ka ts'ebetso e phahameng haholo, sehlahisoa sena se lula le boemo bo ke keng ba nkeloa sebaka indastering ea li-welding le indasteri ea kalafo ea mocheso.

Tlhaloso e qaqileng