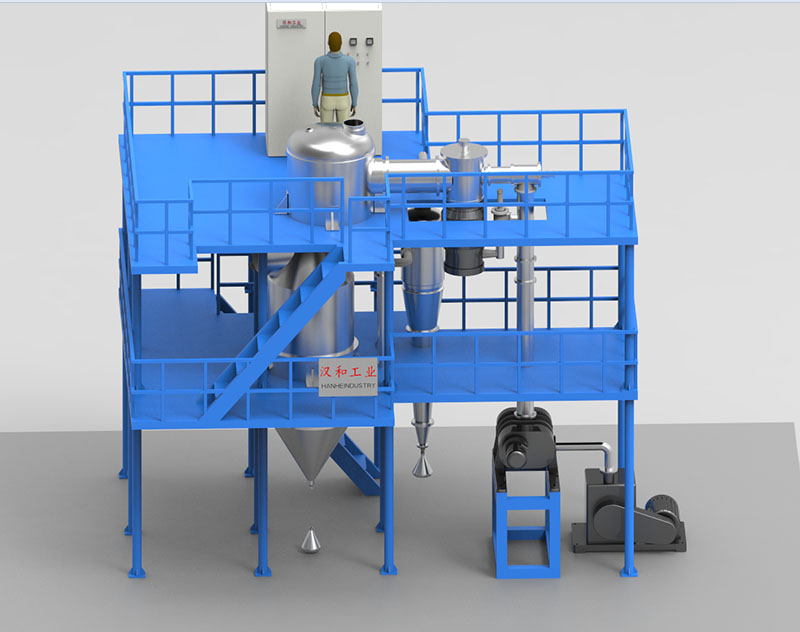

Spherical Metal Powder Gas Atomization Equipment

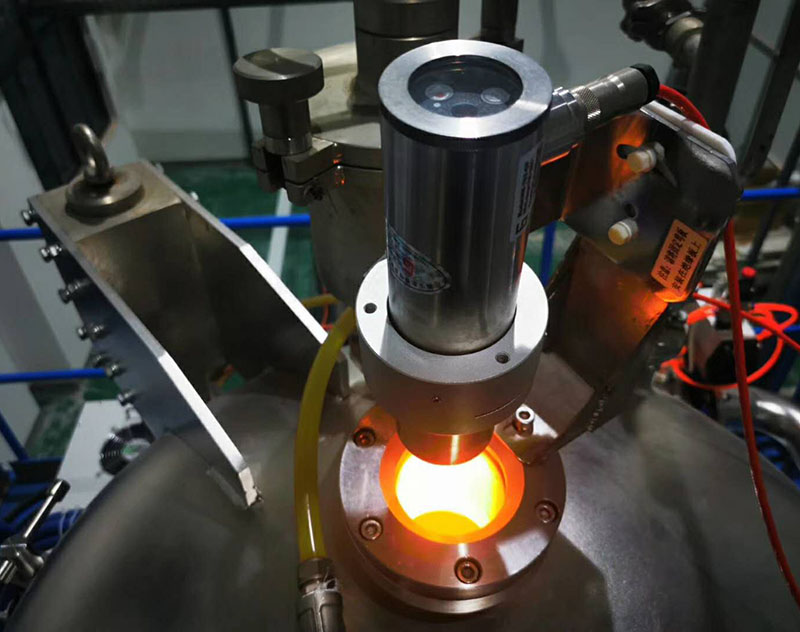

Molao-motheo oa ts'ebetso: ho qhibiliha litšepe tlas'a maemo a nepahetseng a vacuum, 'me u kenye litšepe tse metsi ka sebōping sa ho futhumatsa.Ho tloha ka tlase ho sebōpi sa induction, tšepe ea metsi e phalla fatše ebe e fetisa molomo.Moea o phallang ka khatello e matla o kena ka har'a molomo o thata o kopanyang ebe oa petsoha ebe o etsa atomize tšepe e metsi marotholing a mangata a manyane.Marotholi ana a manyenyane a metsi a tla tiea ha a fofa.Motsoako oa li-powders le moea o tla romelloa ho karohano ea leholiotsoana ka phala ea convener.'Me li-powders tse bohale le li-powders tse ntle hammoho le khase ea atomizing li tla aroloa ka har'a karohano.Li-powders tsa tšepe li tla bokelloa ka sejaneng se tiisitsoeng.

Theknoloji ea atomization ea tšepe ea phofo ea tšepe e sebelisoa haholo-holo bakeng sa tlhahiso ea phofo ea tšepe ea maemo a holimo le litlhoko tsa theknoloji e phahameng.Matšoao a mantlha a tekheniki a phofshoana ea atomo e inert ea khase ke tse latelang: tekanyo e phahameng ea sphericity, bohloeki bo phahameng, oksijene e tlase, ho tiea ka potlako, sebopeho sa micro-homogeneous joalo-joalo.

Likaroloana

1. Boholo ba litšepe le li-alloy powders tse ke keng tsa etsoa ke atomization ea metsi li ka lokisoa ka theknoloji ea khase ea atomization.

2. Li-powders tsa spherical kapa sub-spherical li ka lokisoa.

3. Ka lebaka la ho felisoa ha karohano nakong ea ho tiisa, li-powders tse ngata tse khethehileng tsa alloy li ka lokisoa.

4. Boholo ba phofo bo ka fihla moeling o hlokahalang ka mokhoa o nepahetseng.

Tekheniki Parameters

| Mohlala | Boholo(KG) | Matla (KW) | Khafetsa.(Hz) | Phallo ea Metsi a Pholisa(T/h) | Khatello ea Metsi a Pholisa(Mpa) | Max Temp.(℃) |

| GA-1 | 1 | 20 | 2500 | 8-12 | 0.3 | 1800 |

| GA-3 | 3 | 25 | 2500 | 8-12 | 0.3 | 1800 |

| GA-5 | 5 | 30 | 2500 | 8-12 | 0.3 | 1800 |

| GA-10 | 10 | 60 | 2500 | 15-20 | 0.3 | 1800 |

| GA-25 | 25 | 100 | 2500 | 15-20 | 0.3 | 1800 |

| GA-50 | 50 | 160 | 1000 | 30-40 | 0.3 | 1800 |

| GA-100 | 100 | 200 | 1000 | 30-40 | 0.3 | 1800 |

| GA-200 | 200 | 250 | 1000 | 50-60 | 0.3 | 1800 |

| GA-300 | 300 | 300 | 1000 | 60-80 | 0.3 | 1800 |

| GA-500 | 500 | 400 | 1000 | 60-80 | 0.3 | 1800 |

| GA-1000 | 1000 | 800 | 1000 | 80-100 | 0.3 | 1800 |

Litlhaloso tse ling li ka etsoa ka mokhoa o ikhethileng

Tšebeletso ea ka mor'a thekiso

Re na le lienjiniere tse hloahloa tsa ho kenya le ho lokisa lisebelisoa, le ho fana ka nako ea tiisetso ea lilemo tse 1-3 bakeng sa boleng ba lisebelisoa.Baenjineri ba rona ba ikarabellang bakeng sa lits'ebeletso tsa kamora ho rekisa ba tla etela khafetsa tekheniki bakeng sa ts'ebetso ea hau hantle.

Tlhaloso e qaqileng